There’s so much more to binding than just paperback or hardcover. From the look to the weight to the longevity of the finished publication, it’s important to know how each binding technique can suit the unique needs of your publication and differentiate you from the competition.

In this series, we explore how different binding processes are performed in a commercial setting and how they affect the final product.

What is case binding?

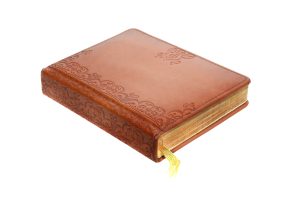

Case binding is a binding method used for hardcover books which involves encasing sewn or perfect-bound book blocks in covers of various materials. Valued for their durability, casebound products are designed to not only last for decades of frequent use but also to provide a beautifully crafted published work with seemingly endless possibilities.

Assembly required

The industrial construction of a casebound publication varies between machinery and binderies, but the basic process is as follows.

After the inner pages of a publication are printed and folded into signatures, a gatherer sorts them in the correct sequence to create what is called a book block. Different binding methods can be finished with a hardcover to become a casebound product, but the most widely used process for casebound products is Smyth case binding.

In this method, signatures are sewn together to create a book block. The book block undergoes nipping or smashing to compress the spine of the book and shape the spine to fit into its cover effectively. Adhesive is applied to the spine of the book block in the gluing off process and bracket tape is used to reinforce the spine’s binding and shape. An inline three-knife trimmer is then used to trim the three unbound edges of the book block to the final trim size.

Please visit Binding Basics – Sewn Binding for an in-depth description of sewn binding.

At this stage, a variety of embellishments can be added, including edge treatments, headbands and bookmarks. Edge treatments include enhancements like edge printing, staining and gilding, where dye, colorants or gold leaf is applied to the non-spine edges of the book block. Headbands are strips of decorative cotton or silk that are attached to the top and bottom of the spine, and bookmarks are cords or ribbons which are attached to the top of the spine to serve as ornamental placeholders.

Covers and endsheets are each prepared separately before the final assembly of a casebound book. Although there are many ways to design covers, the process of making covers consists of a few key steps. If the cover material is able to be printed on, such as paper or linen, the cover is preprinted before it is trimmed to size. Covers are cut to be larger than the case and cuts or fold marks are made on the corners to ensure the cover folds around the case cleanly. Some cover applications, such as lamination or UV, are applied to the cover before casing in, while others, like hot foil or embossing, are applied after casing in.

Covers and endsheets are each prepared separately before the final assembly of a casebound book. Although there are many ways to design covers, the process of making covers consists of a few key steps. If the cover material is able to be printed on, such as paper or linen, the cover is preprinted before it is trimmed to size. Covers are cut to be larger than the case and cuts or fold marks are made on the corners to ensure the cover folds around the case cleanly. Some cover applications, such as lamination or UV, are applied to the cover before casing in, while others, like hot foil or embossing, are applied after casing in.

During the process of casing in, a three-paneled board is trimmed and fed into a case making machine, which attaches a backlining over the boards a cloth backlining over the board. This board is usually made of cardboard or chipboard and can come in various weights. The inside of the cover is then coated in glue and pressed onto the base board. The excess cover material is folded around the board and secured in place with glue.

Finally, adhesive is used to coat the endsheets, which attached the outside pages of the book block to the inside of the hard cover. The spine of the book block is then glued to backing material which wraps around the binding and spans between the spine creases.

Weighing the options

The intensive case binding process produces excellent-quality printed works that will last a lifetime, if not longer. This is beneficial for library-quality books, durable yearbooks and textbooks and great for special-edition runs. The professional look and feel of the finished product is a benefit for customers who value the artisanship of well-crafted books. In the Smyth case binding process, the spine of the book block is adhered to the backlining instead of the inside of the case, which allows the pages to lay flat when opened.

The options for casebound covers provide virtually limitless opportunities for creativity and design. There are a large variety of cover applications, including the following options:

- Spot or flood lamination with gloss, matte or gritty finishing

- Spot or flood UV with gloss, matte, satin or gritty finishing for glow-in-the-dark, thermochromic or photochromic effects

- Die options such as hot foil, metal gloss, embossing and debossing

- Laser cutting for covers and endsheets

- Branding (provides a partial burn into case)

- Clear or colored silk screen

- Graining

- Lenticular or crack-and-peel tip-ons

- Scented varnishes

- Namestamping

Cover materials like paper, cloth, leather or plexiglass can be used for case binding, and in some cases multiple materials can be used on the same case, known as quarter-bound, half-bound or three-quarter-bound covers. Slip cases, belly bands, trapper keeper covers and dust jackets can be created to wrap around the outside of the finished book.

Cover materials like paper, cloth, leather or plexiglass can be used for case binding, and in some cases multiple materials can be used on the same case, known as quarter-bound, half-bound or three-quarter-bound covers. Slip cases, belly bands, trapper keeper covers and dust jackets can be created to wrap around the outside of the finished book.

Case binding allows for an optimal balance of durability and design, and is an excellent option for trade books, coffee table books, art portfolios and children’s books in addition to textbooks, yearbooks and library books. If cover options are important to the finished product, case binding is a great method to employ impart creativity into a book’s design. Case binding results in a beautiful product that will outlast most other publications on the bookshelf.

If you are considering case binding with Walsworth or you would like to speak with someone regarding your next print project, our knowledgeable staff can help you find the best option suited to your needs.